Though you may have heard the term ‘rough sawn lumber,’ it’s quite likely that you don’t really know what that means. So, let’s define it. Really, this refers to lumber that isn’t yet finished before it’s shipped to be sold. It is kept rough intentionally and must be dried, planed or dressed as the recipient wishes.

What exactly happens is that lumber when processed at a mill, sawing it of its roughness is an early step at a time when the boards of the tree haven’t been planed or dried. It continues to be green when shipped, proving that it has neither dried nor cured. So, it will shrink later as it contains 20% water and must be dried under the sun before use.

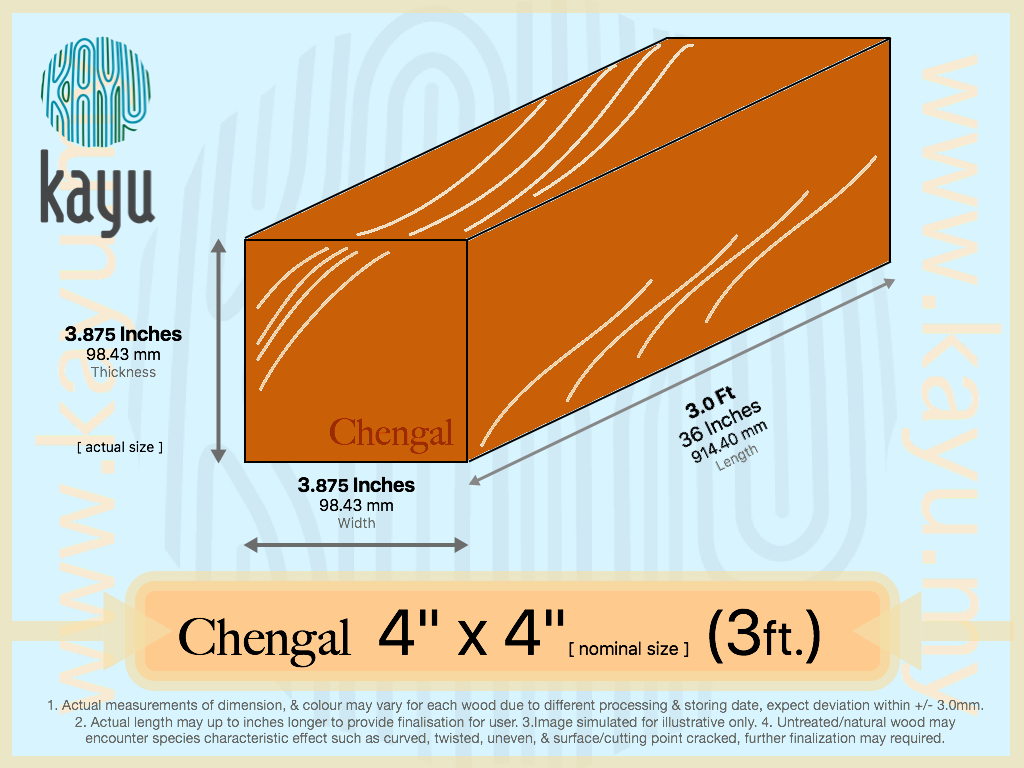

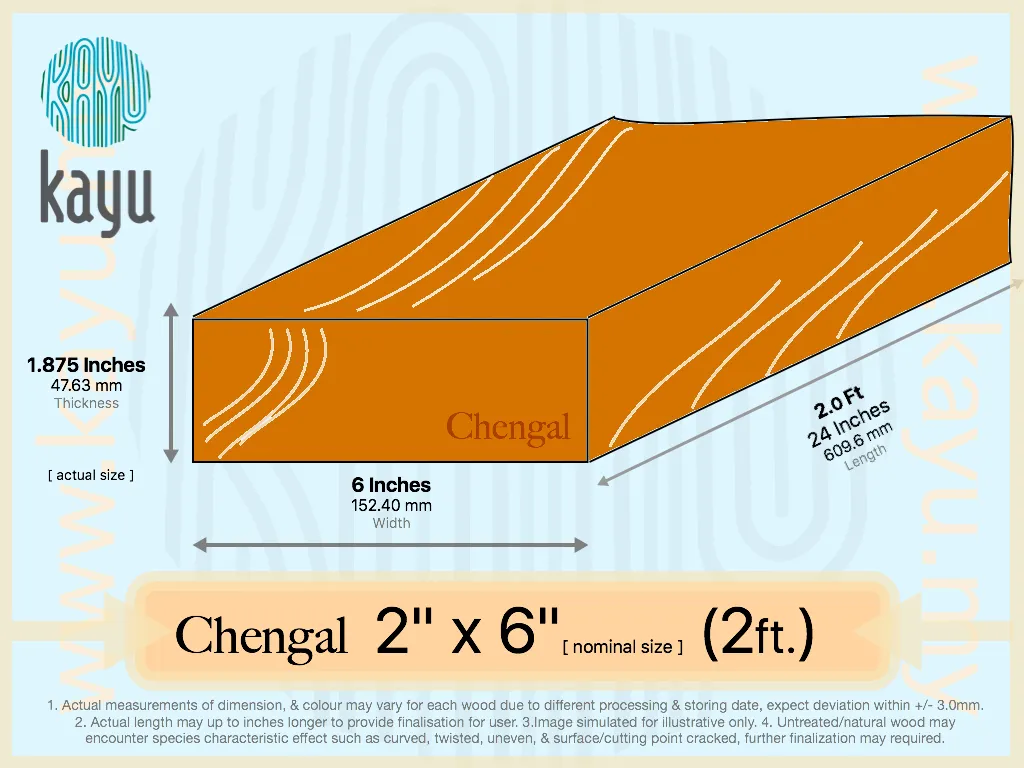

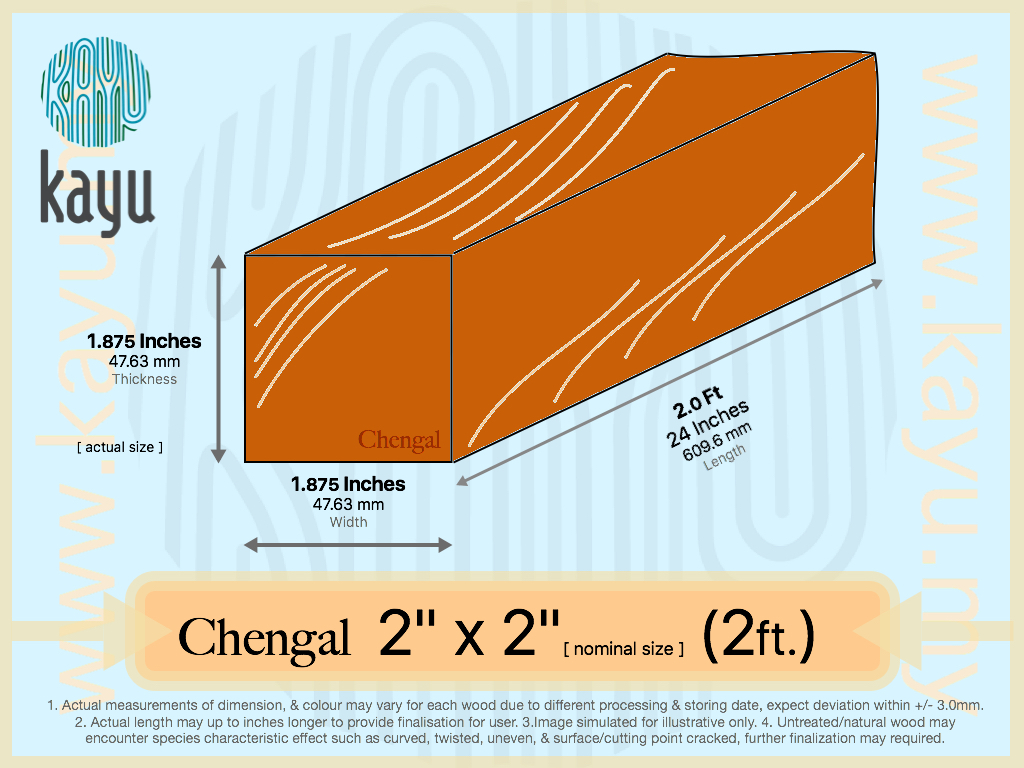

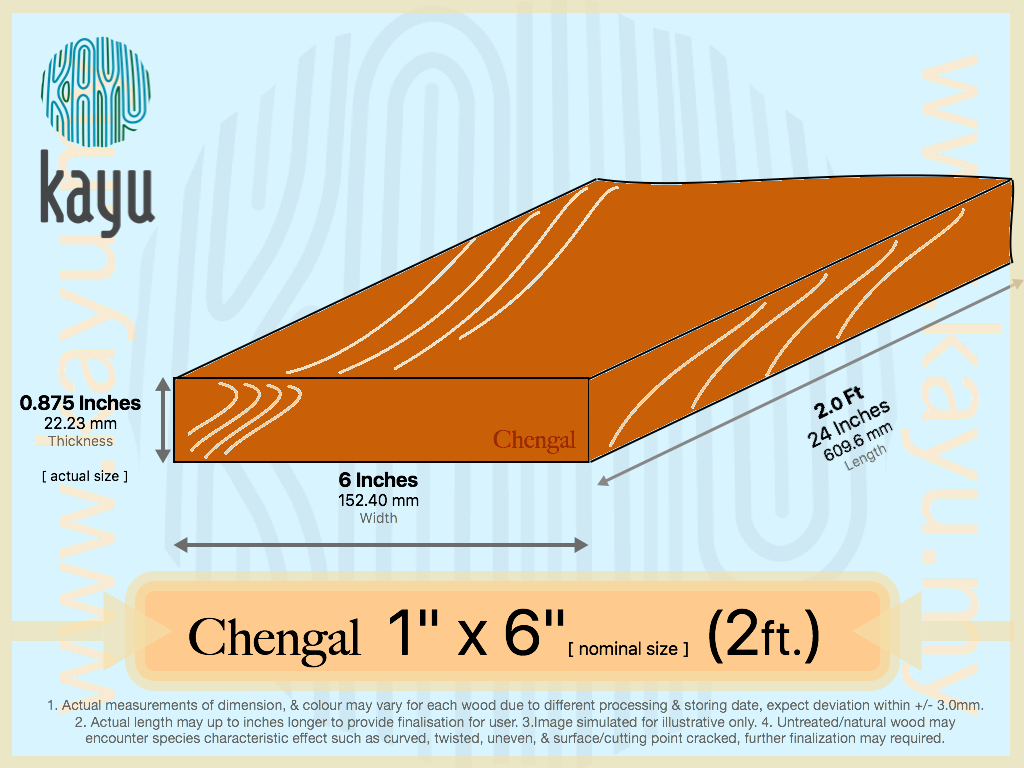

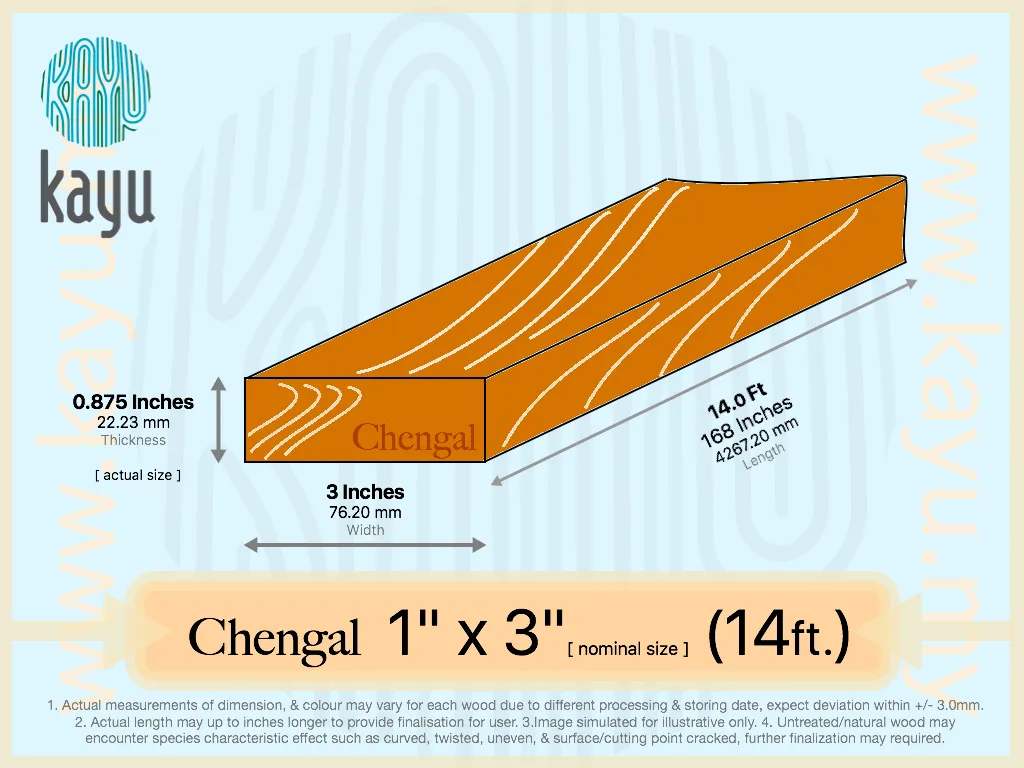

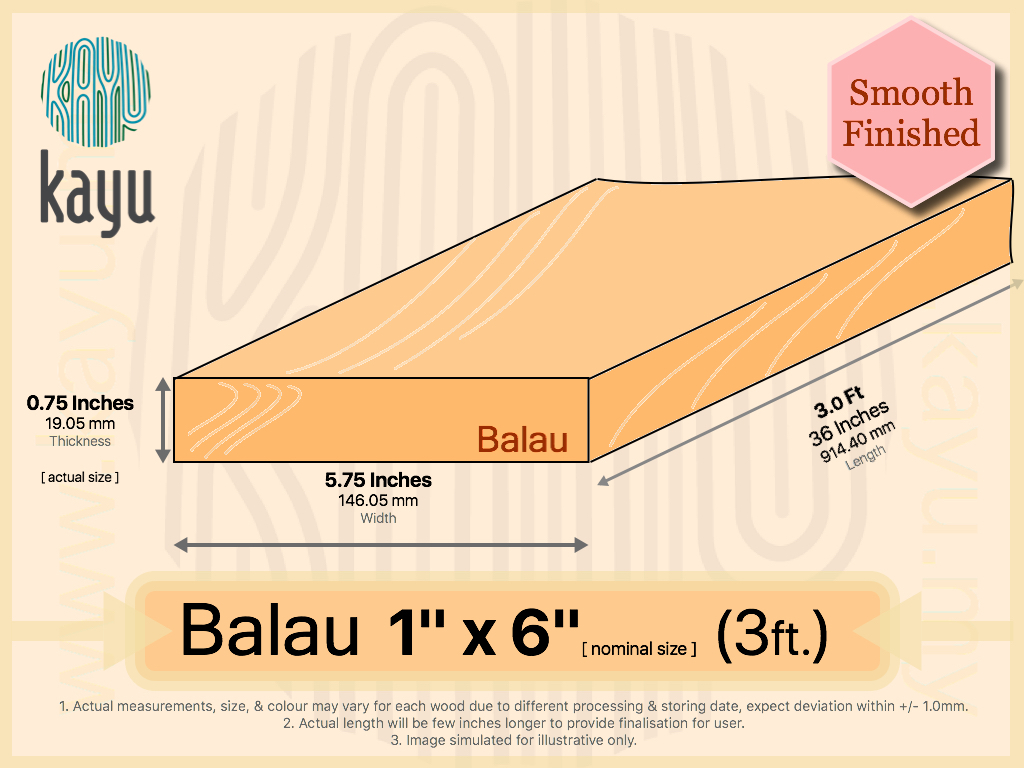

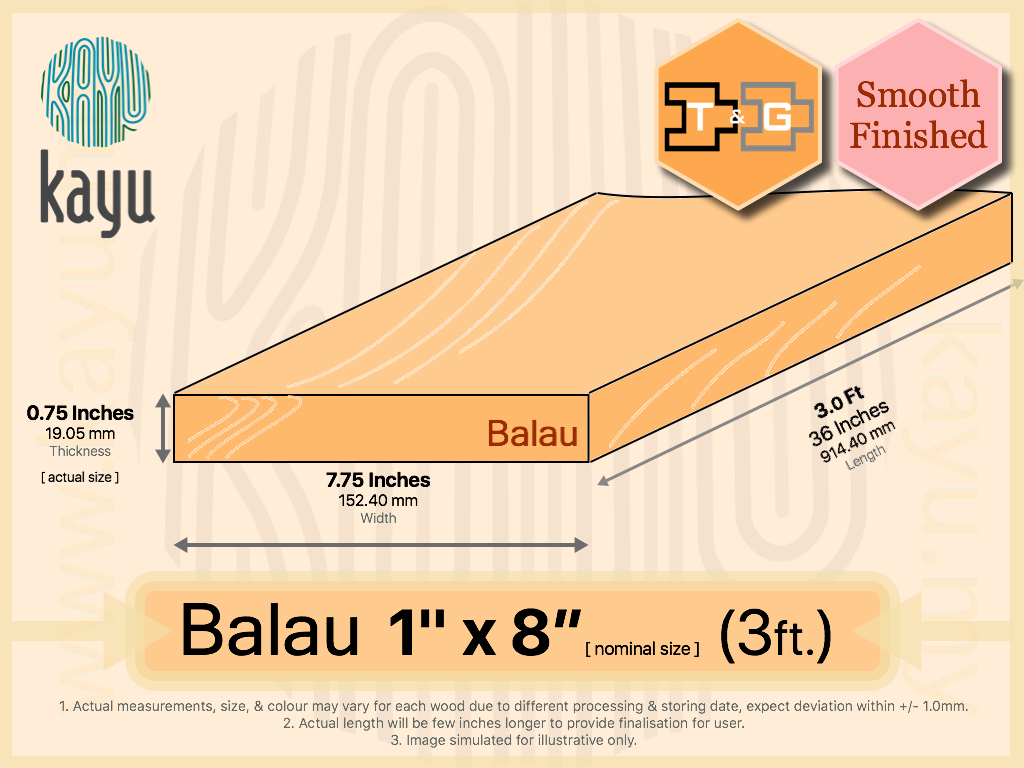

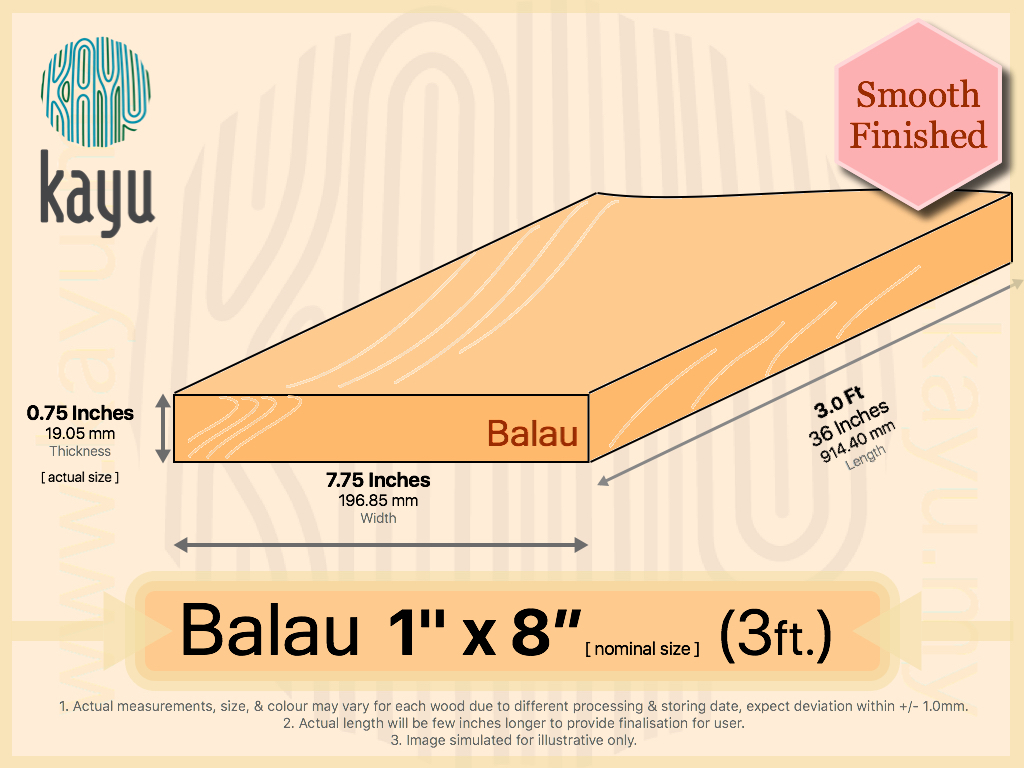

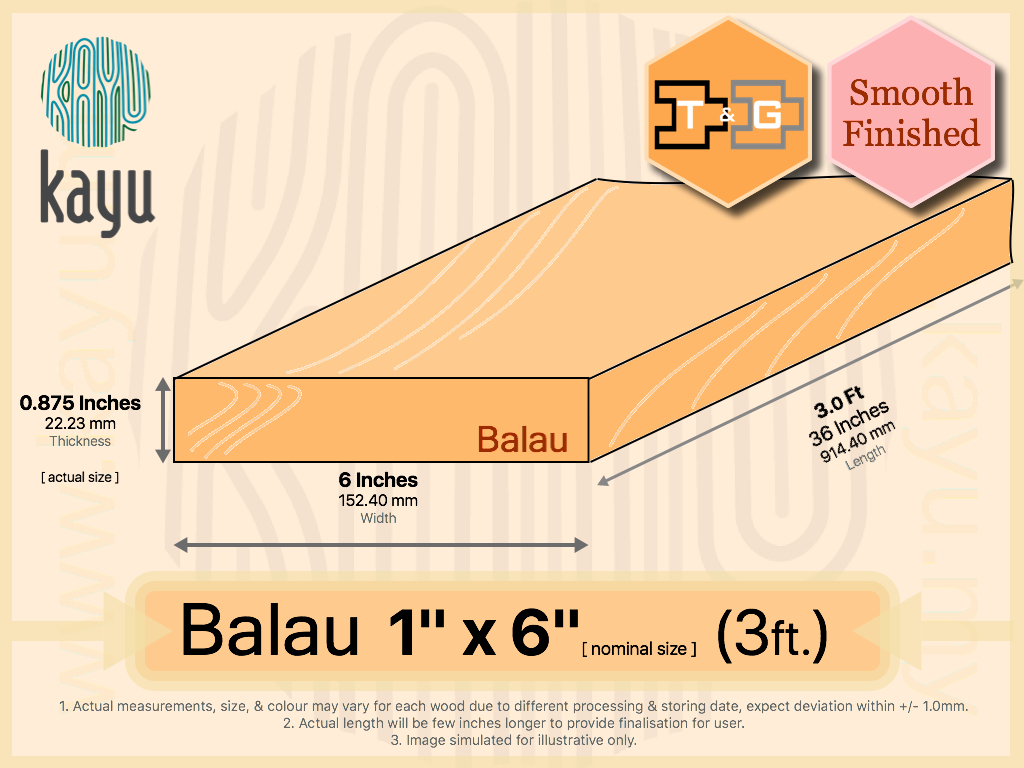

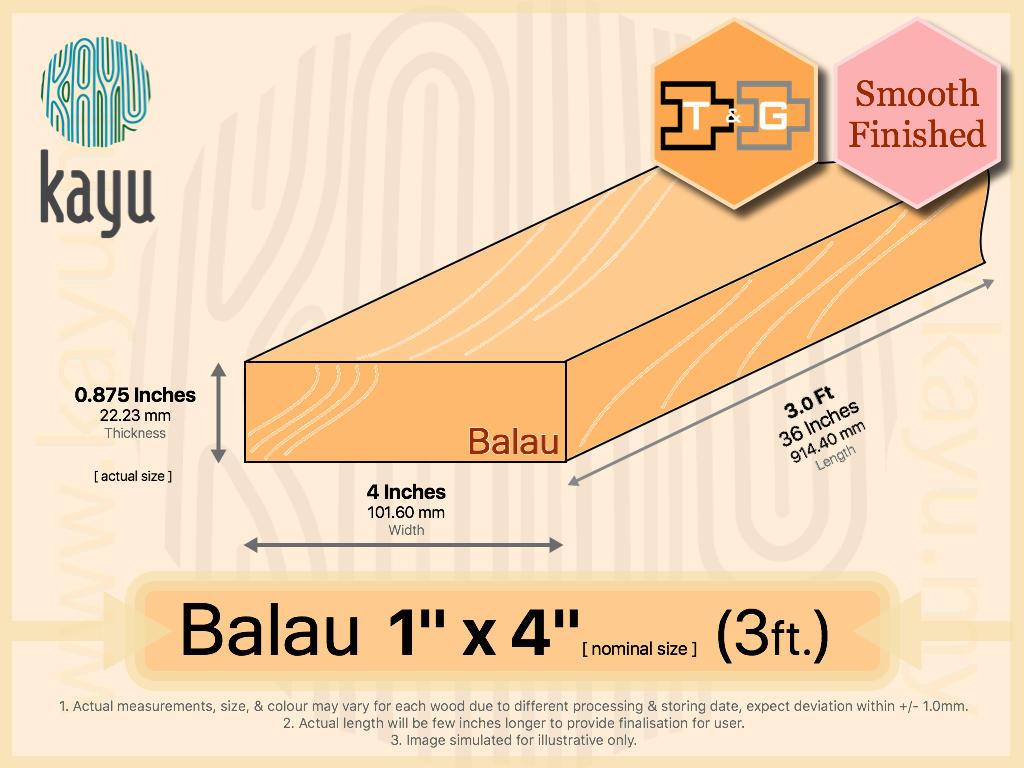

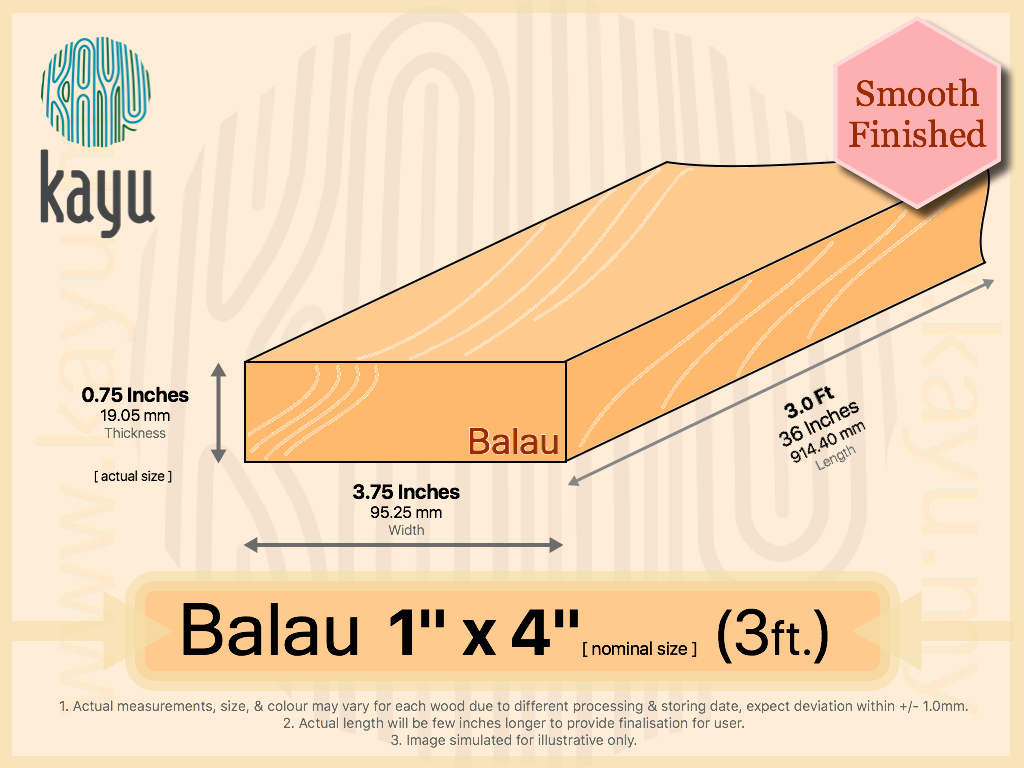

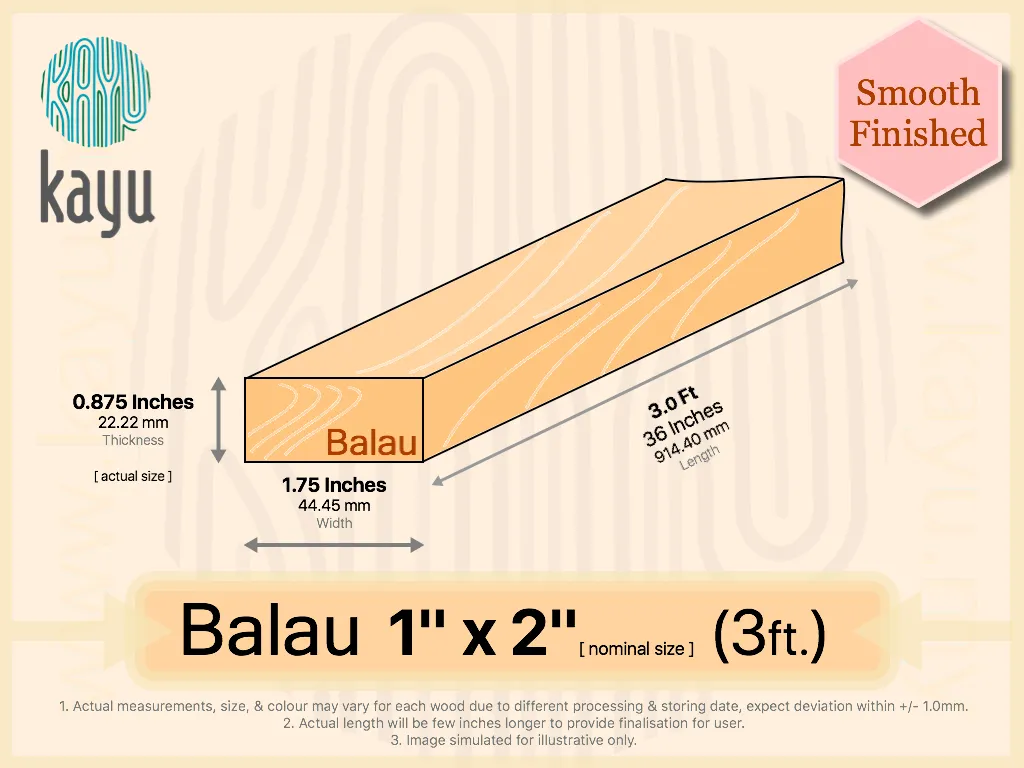

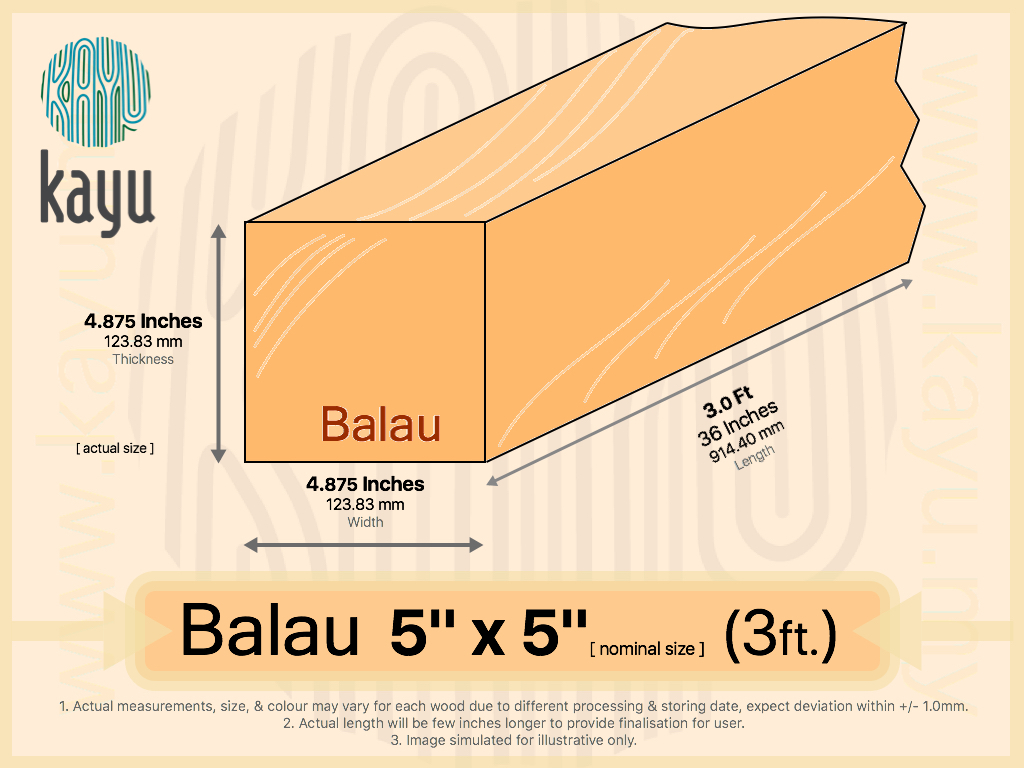

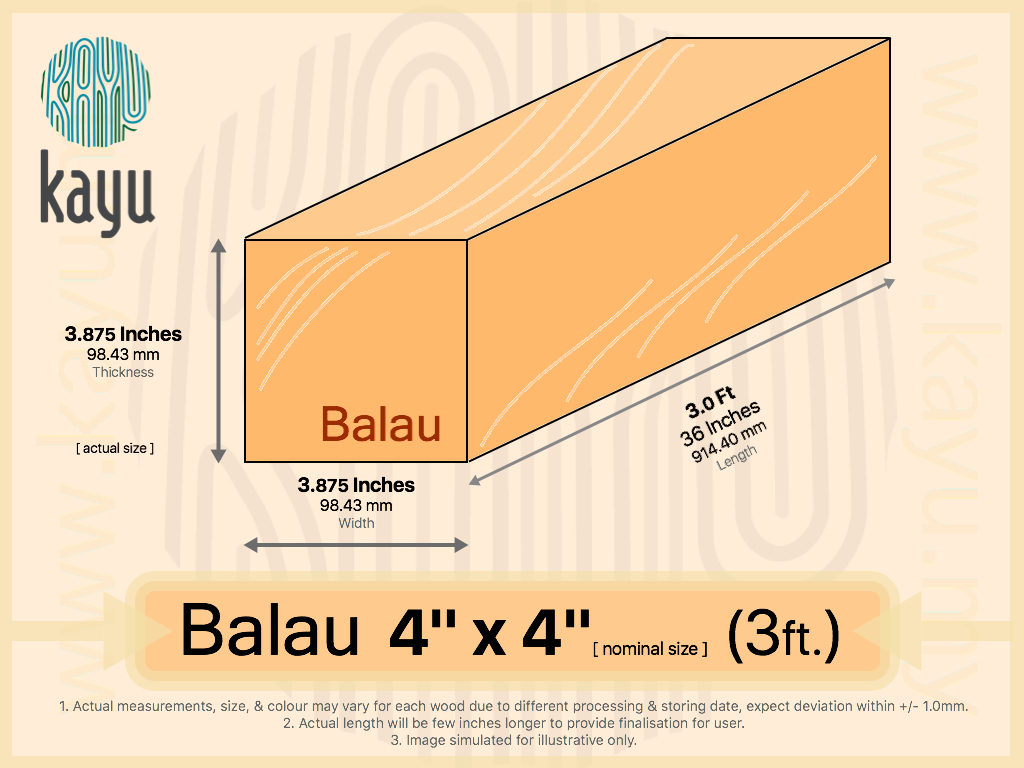

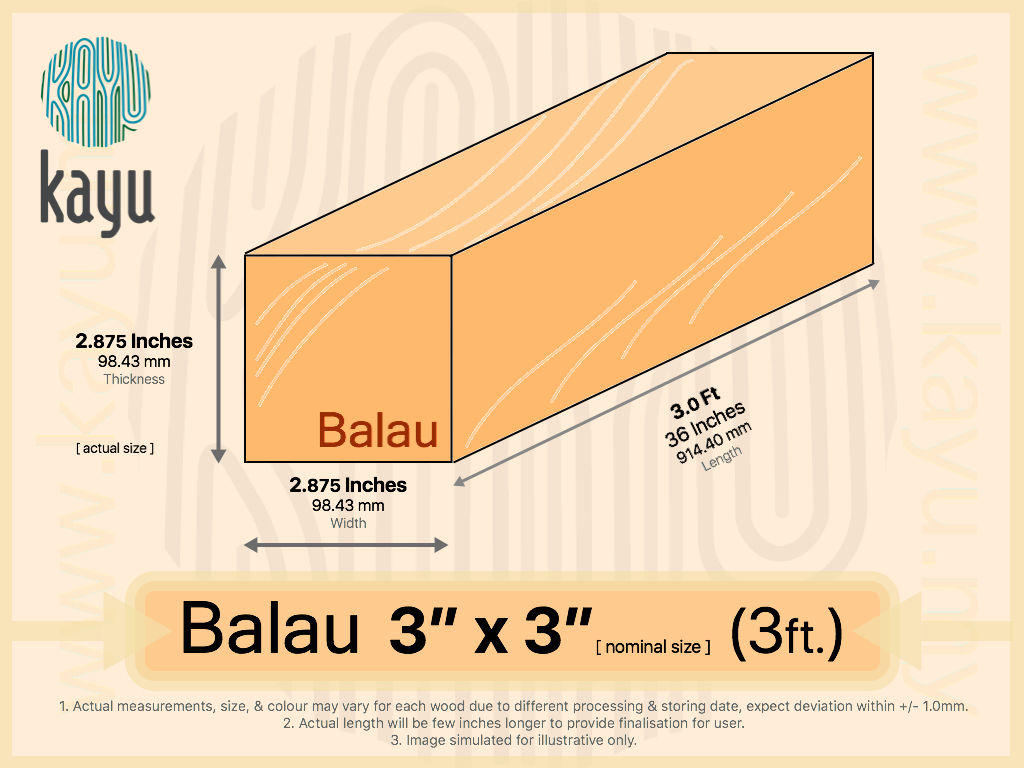

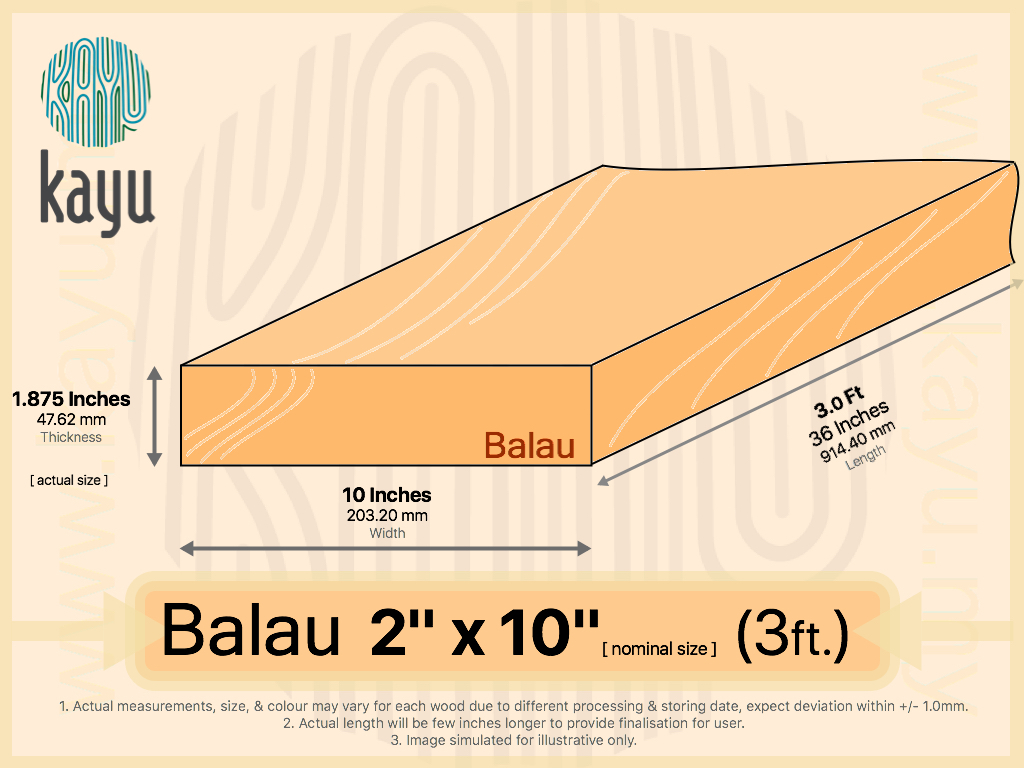

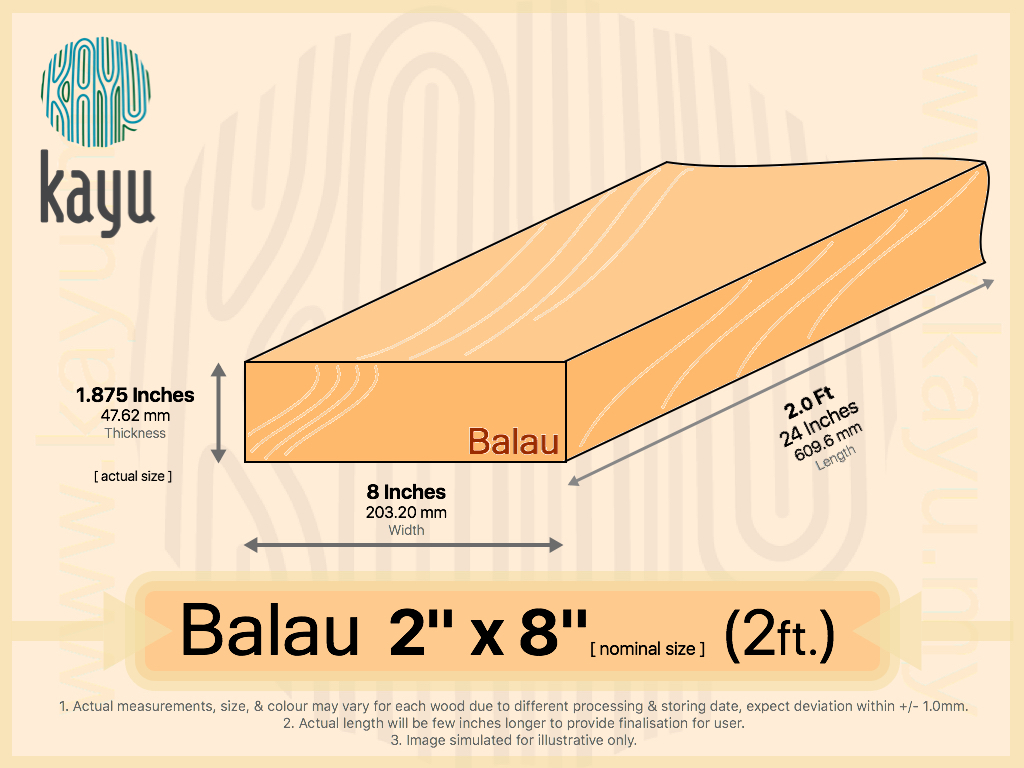

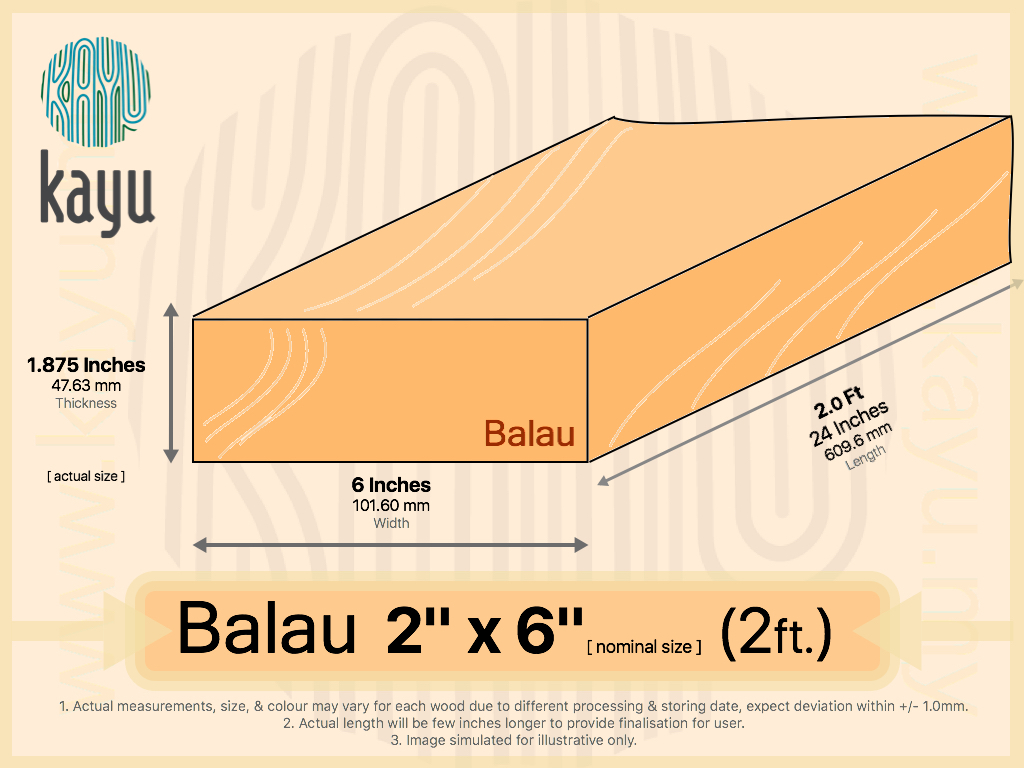

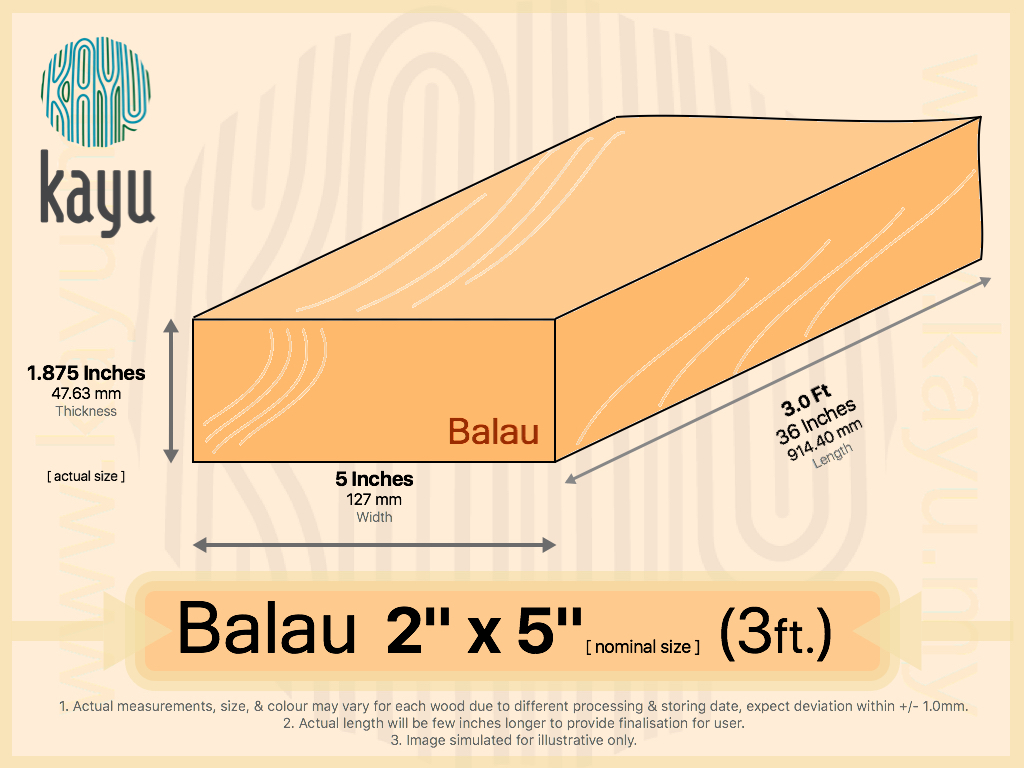

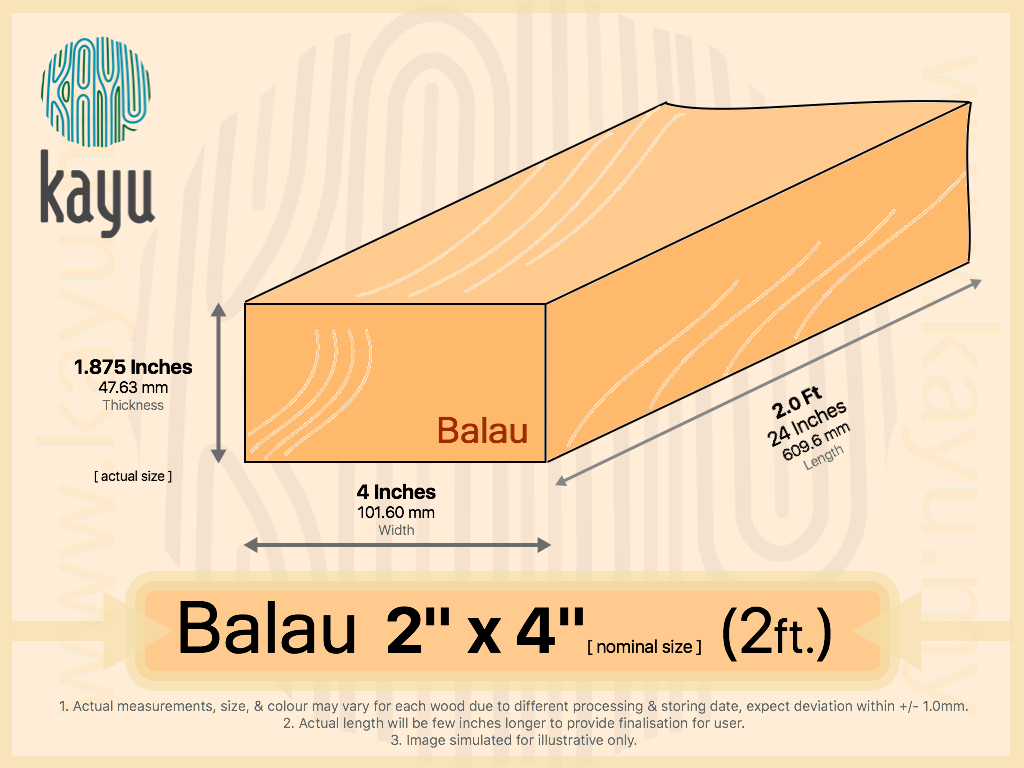

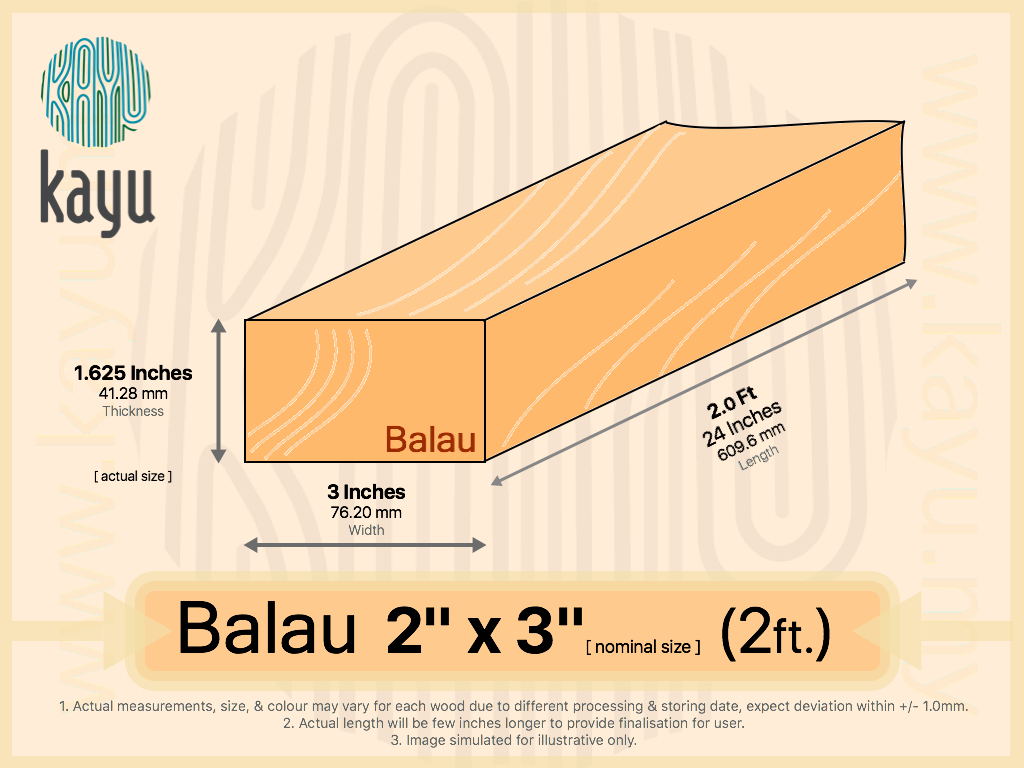

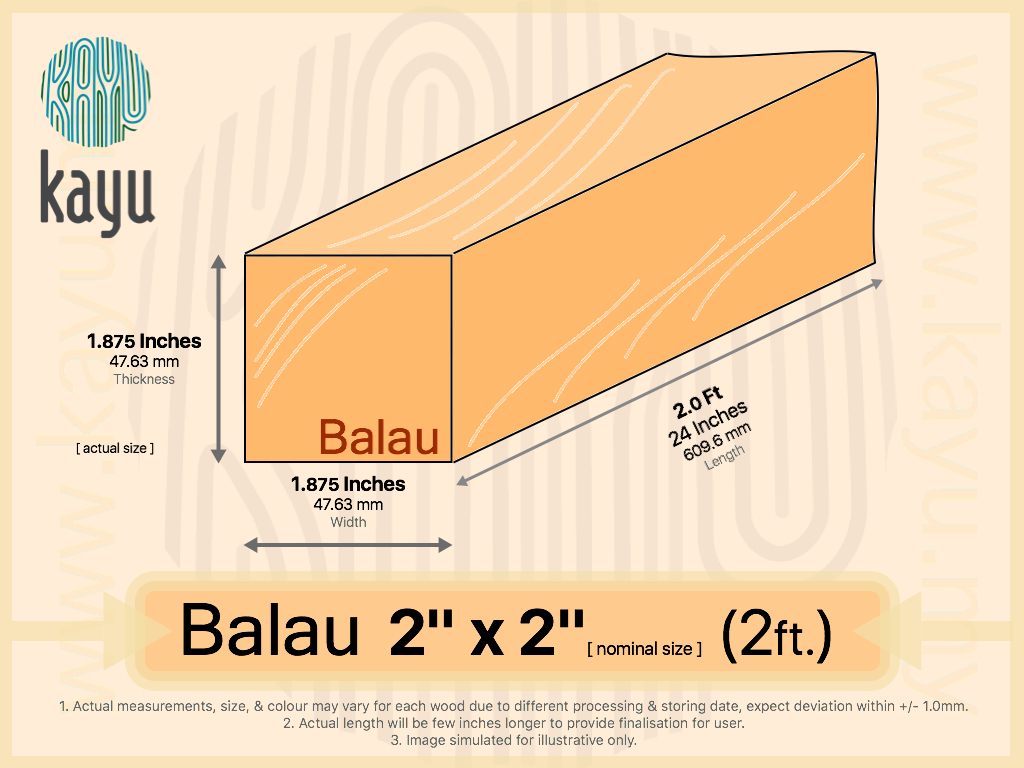

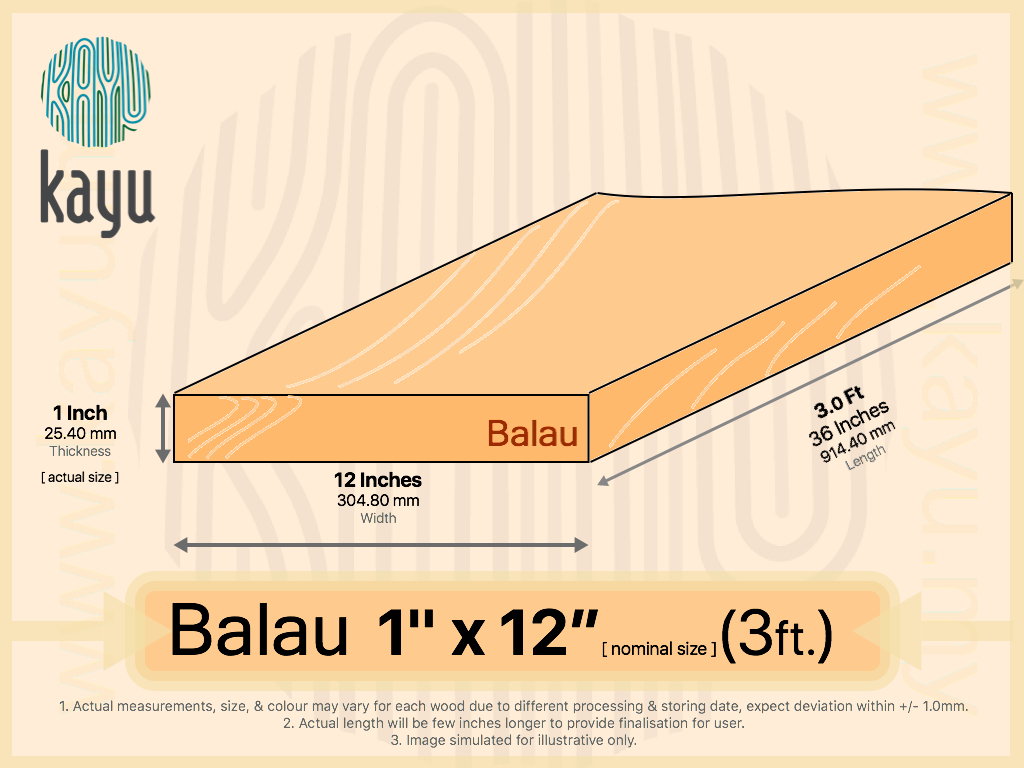

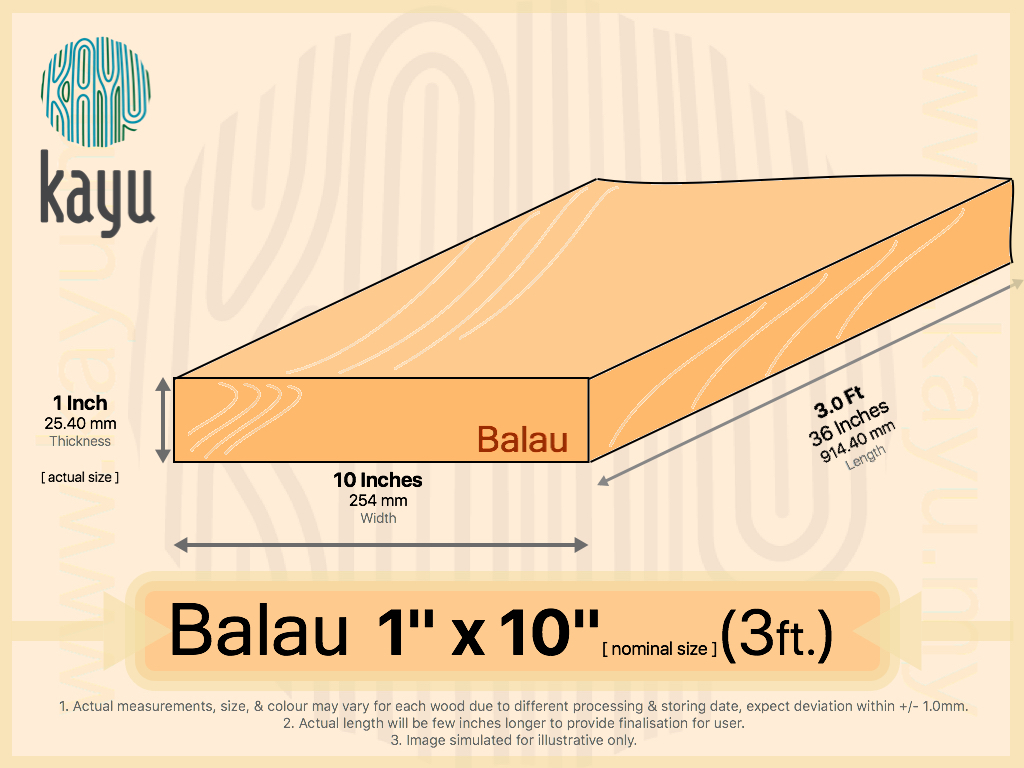

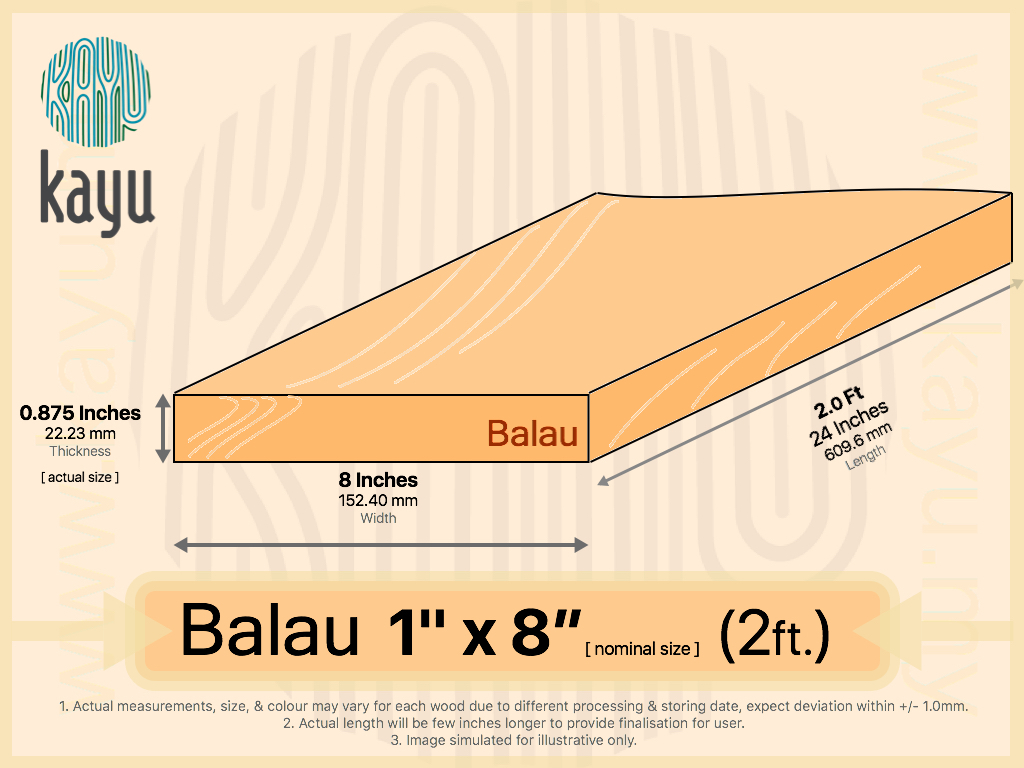

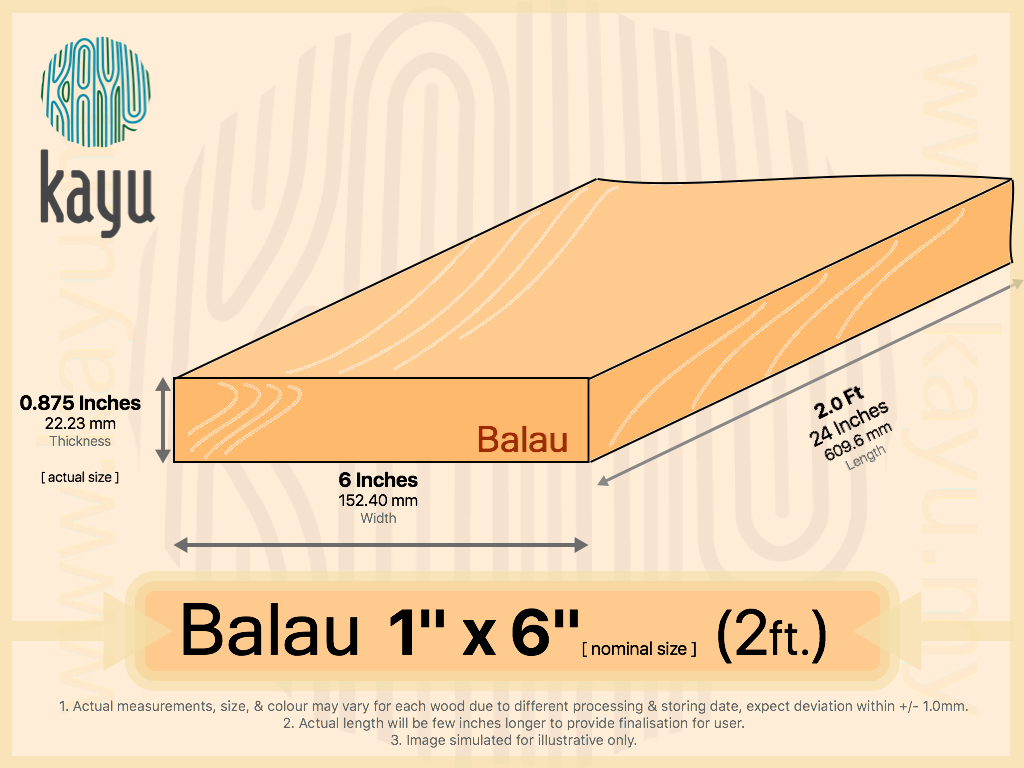

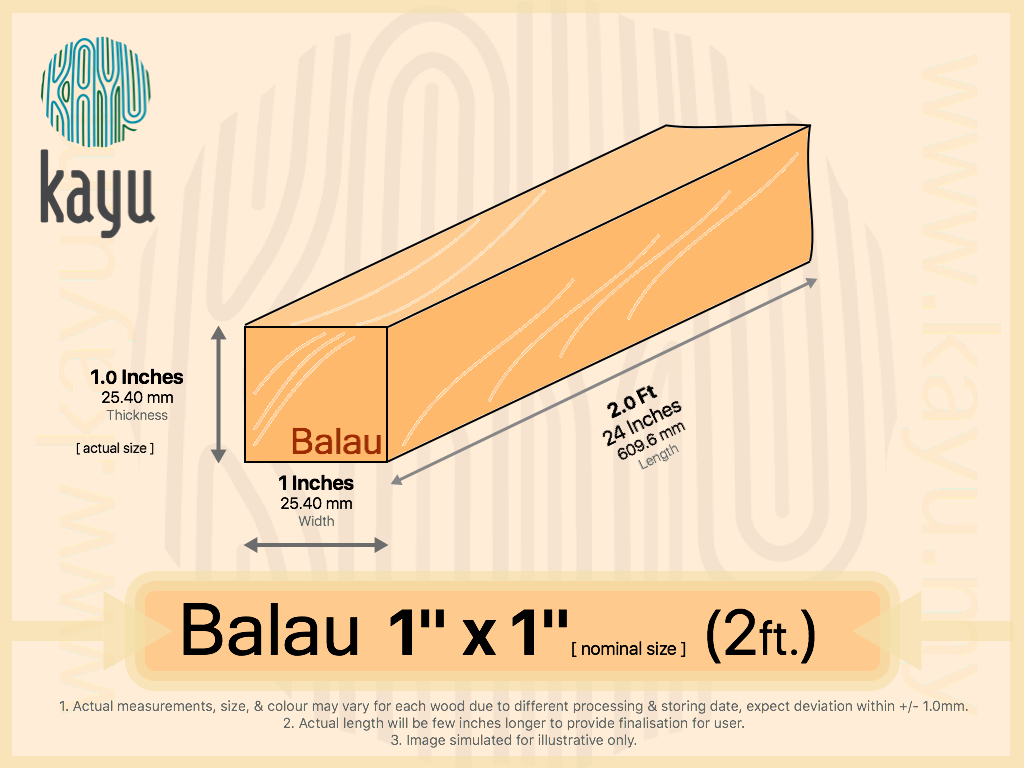

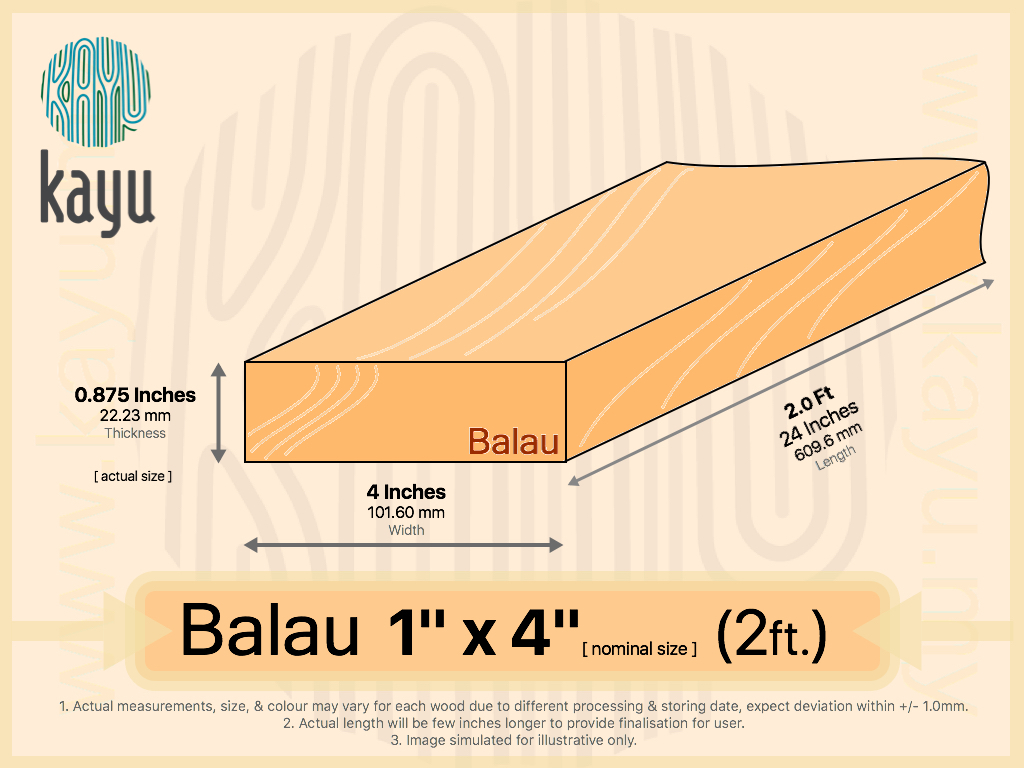

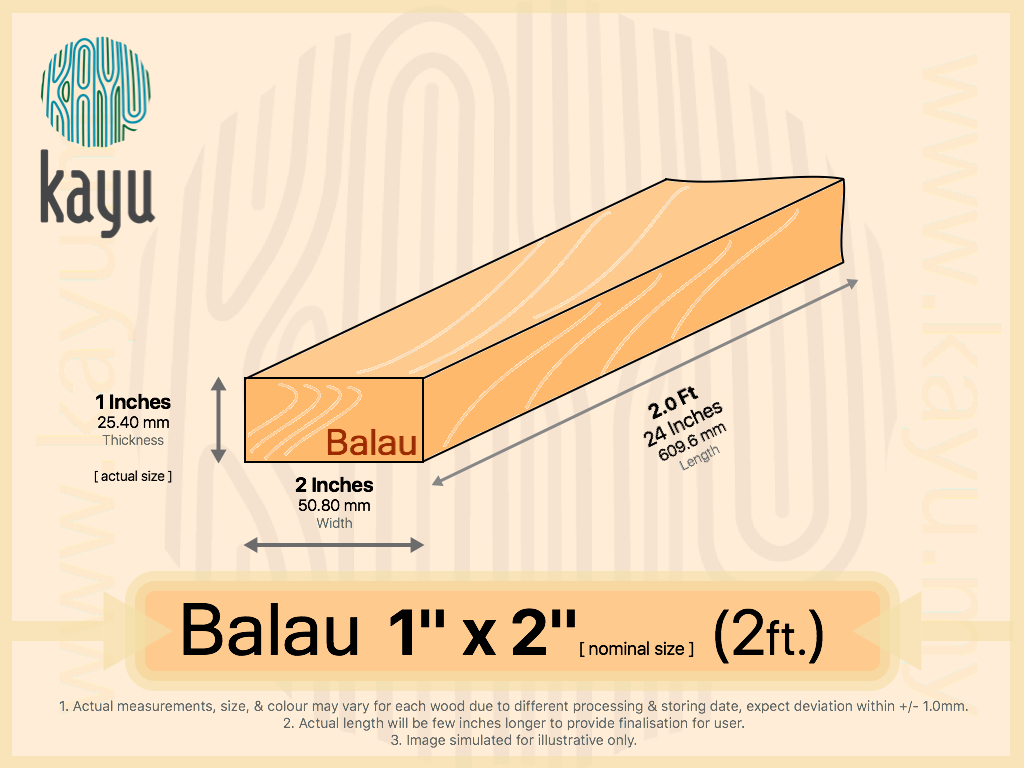

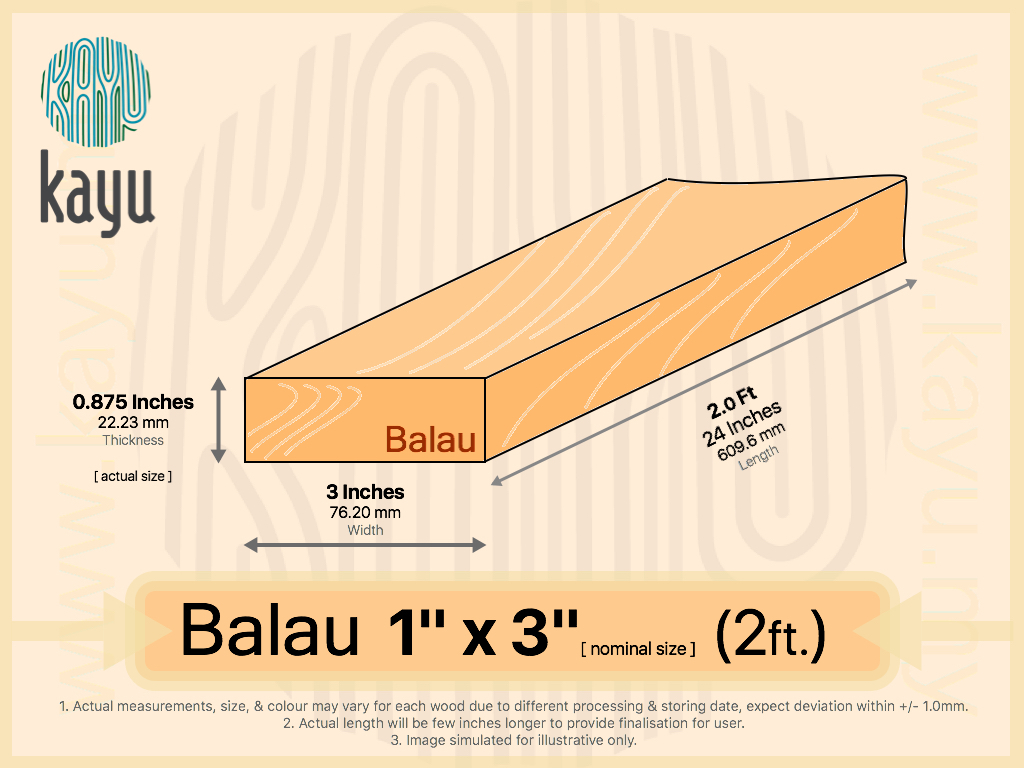

Because it is yet to shrink, it is larger than its finished counterpart, leaving enough room for planing and smoothing. People prefer to by this lumber as it’s relatively inexpensive and it allows them to have greater control.

Advantages of using rough sawn lumber:

- This lumber is usually sold cheaper than finished lumber.

- It is also thicker than finished wood.

- It allows the woodworker to have enough wood for a good margin of error, while also saving money.

- DIY woodworkers and hobbyists prefer rough sawn lumber for their projects as it is economical and they can work with quality wood.

- It is ideal for a large spectrum of furniture-making.

- Since it isn’t milled, this kind of wood can give a really rustic feel.

- This type of wood creates less of an environmental impact since it is only air-dried.

- Usually, exotic woods that bear rich hues and designs are always rough sawn.

Information shared by "thebasicwoodworking.com".